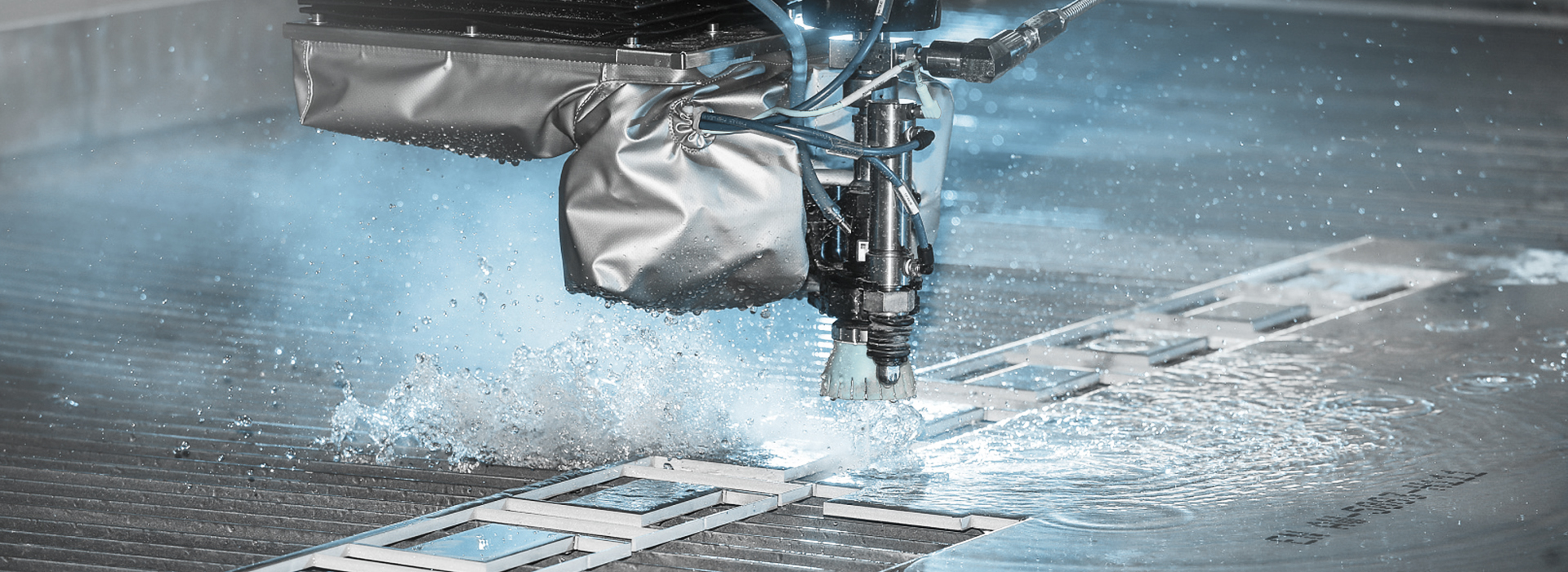

Water jet cutting

Highest Precision – water jet cutting

Our profile

- Certified according to EN 9100 | EN 9120 | ISO 9001 | ISO 14001

- for the aerospace industry

- Quality assurance processes

- Fast implementation

- Expert consultation

- Well-known customers from all industries

Our guarantee

HIGHEST PRECISION

The WMH GROUP GERMANY offers waterjet services for high-precision parts across various industries. These parts meet requirements by adhering to the international standard ISO 2768-m for tolerances in manufacturing technology. Tighter tolerances can also be achieved upon request.

COMPLEX SHAPES

Our CNC-controlled waterjet cutting systems enable the most precise processing of complex shapes and contours from materials such as aluminium, titanium, and other metals with minimal tolerances.

VARIABLE PRODUCTION

Whether small quantities or large production runs, our waterjet technology covers all requirements from prototypes to mass production.

FAST IMPLEMENTATION

We guarantee a fast and precise implementation of projects. Our experienced team ensures our high-quality standards are met by adhering to quality assurance processes.

MINIMAL POST-PROCESSING

Using high water pressure preserves the structure and composition of the material and creates cut surfaces that appear sandblasted, without being affected by heat. This reduces the need for further surface treatment of the cut area and any subsequent costs due to post-processing.

Individual processing

WMH GROUP GERMANY‘s waterjet services use CNC-controlled waterjet technology to quickly, precisely, and efficiently process materials. The waterjet is generated by an ultra-high-pressure pump with up to 4,130 bar and is guided through a nozzle.

This high pressure, combined with an abrasive component, enables us to process materials such as aluminium, titanium and other metals.

High-precision components with complex contours and shapes are not a problem for us. The waterjet cutting technique allows us to produce parts with sizes of up to 1,920 mm x 3,920 mm and material thicknesses of up to 140 mm. With a linear axis accuracy of +/- 0.04 mm/m, we are able to maintain tolerances according to customer specifications.

TECHNICAL SPECIFICATIONS

- CNC-controlled waterjet

- High pressure of up to 4130 bar

- Abrasive components (Garnet sand)

- Materials: Aluminium, Titanium etc.

- Size: max. 1.920 mm x 3.920 mm

- Material thickness: max. 140 mm

YOUR BENEFITS

- High-precision parts, tolerances according to your specifications (ISO 2768-m guaranteed)

- Complex shapes possible

- Variable production: prototype, single piece, mass production

- Cold cutting process, structure and texture remain stable material. Does not discolour due to heat.

Our Partners

Your contact person

Are you currently trying to source aluminium solutions, or are you planning a project? Your personal contact will be happy to help: