Aluminium stoplogs

FOR FLOOD CONTROL, HYDRAULIC ENGINEERING AND SEWAGE WORKS

Stoplogs from the Singen site have a proven record over many years in hydraulic engineering, flood protection, sewage treatment and firewater containment – both the standard design and in many custom-built systems.

Aluminium stoplogs

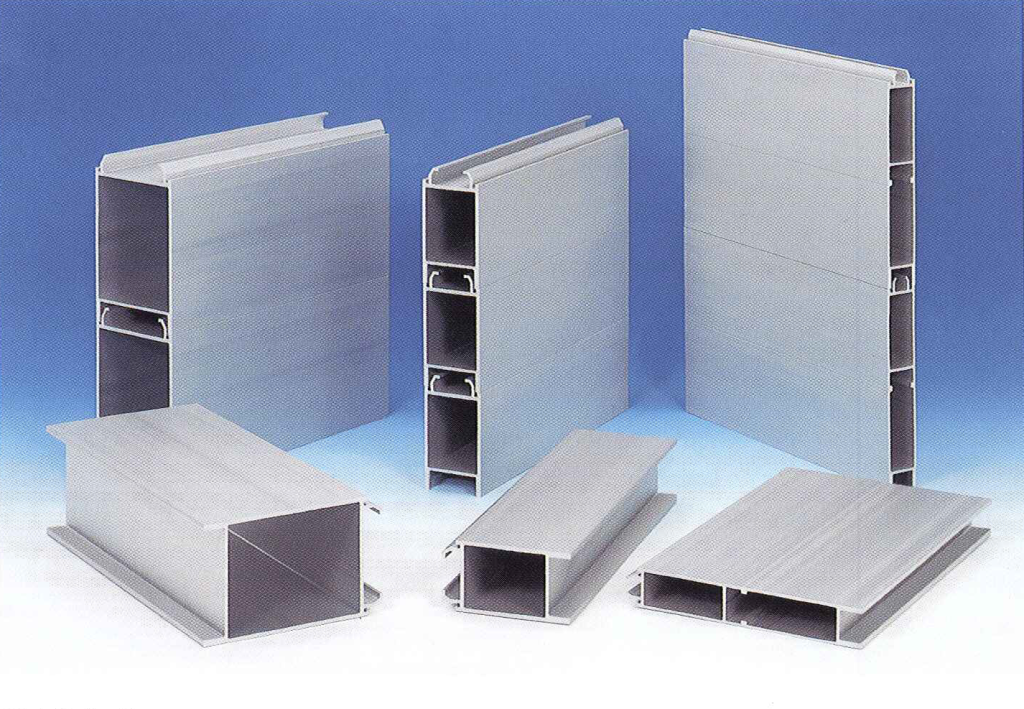

Aluminium has a number of advantages rendering it particularly suitable for stoplogs.

Since stoplogs usually have to be kept available on-site for several years, low maintenance is particularly important. Aluminium is corrosion-resistant, does not need painting, unlike steel, and, unlike wood, is not destroyed by pests. It does not warp and retains its straightness very well. Aluminium extrusion technology allows for the best possible structural cross-section design.

The aluminium logs weigh very little, so can usually be carried and installed by one person. This speeds up assembly and reduces the risk of accidents.

The increasing need to be watertight, especially in flood protection, has led to a new generation of stoplogs with sealing options. Cross-sections are compatible with previous profiles in terms of retro-fit replacements and adding extras.

Water tightness

Traditionally, stoplog barriers were primarily for closing off areas in an emergency, for temporary use, with only a limited amount needing to be watertight. The first generation of stoplogs from Constellium Singen represented a major step forward, as a seal establishes by itself really quickly thanks to the frame holding its shape so well.

The frames in second-generation logs have recesses in the horizontal joints, into which special seals can be pressed if required.

How to create the seal between the lowest log and the invert, as well as to the sides in the guide channels, needs to be looked at on an individual basis. Being absolutely water-tight takes considerable effort. However, this is often not absolutely necessary as self-sealing is an option in some cases, or in others, the groundwater behind the barrier has to be pumped out anyway.

Constellium Singen Aluminium stoplogs System

| Stoplog material | according to | ||

|---|---|---|---|

| EN AW-6060 T 66 | EN 573-3 | ||

| (EN AW-6063 T6 SQ) | EN 573-3 | ||

| Main alloying elements | Al; Mg; Si | ||

| Application | Temporary installation in hydraulic engineering, flood control, sewage technology and fire water retention measure. | ||

| General information | Very well suited alloy for water and other liquid shut-off measures under normal temperature conditions. Very good experience over many years compared to other alloys or other metals. | ||

Specifications

| PHYSICAL PROPERTIES | Weight | EN 1999 | 2,7 g/cm³ | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Modulus of elasticity | EN 1999 | 70 000 N/mm² | ||||||||||||||||||

| Operating temperature range | up to 80°C | |||||||||||||||||||

| Tensile strength | DIN EN 755-2 | 215 N/mm² | ||||||||||||||||||

| Yield point | DIN EN 755-2 | 160 N/mm² | ||||||||||||||||||

| Thermal expansion | EN 1999 | 23 x 10-6/K | ||||||||||||||||||

| Poisson‘s ratio | EN 1999 | 0,3 | ||||||||||||||||||

| Hardness, Brinell | EN 755-2 | ( ~ 70 ) | ||||||||||||||||||

| Weldability | EN 1999 | G-S | ||||||||||||||||||

| CHEMICAL PROPERTIES | Atmospheric, Weathering, UV exposure | VG | ||||||||||||||||||

| Ozone | VG | |||||||||||||||||||

| Aging | VG | |||||||||||||||||||

| Drinking water | VG-G | |||||||||||||||||||

| Wastewater | G | |||||||||||||||||||

| Seawater | DIN 81 249-2 | G-S | ||||||||||||||||||

| Dilute acids* | VG-S | |||||||||||||||||||

| Concentrated acids* | G-P | |||||||||||||||||||

| Diluted alkalis* | G-P | |||||||||||||||||||

| Concentrated alkalis* | S-B | |||||||||||||||||||

| Oils and grease | VB | |||||||||||||||||||

| Petrol | VG | |||||||||||||||||||

| Key |

|

|||||||||||||||||||

Mechanical properties & maximum log cross-sections

EN AW-6063 T6 SQ

according to DIN EN 755-2 and DIN 4113 (formerly AIMgSi0.5 F22)

| Tensile strength | Rm | ≥215 N/mm² |

| Yield point | RP 0,2 | ≥ 170 N/mm² |

| Elongation | A | = 12% |

| Modulus of elasticity | 70 000 N/mm² |

Allowable stresses (tension/compression, load case H)

zul σWEZ = 48 N/mm² (welded)

zul σ = 95 N/mm² (base material)

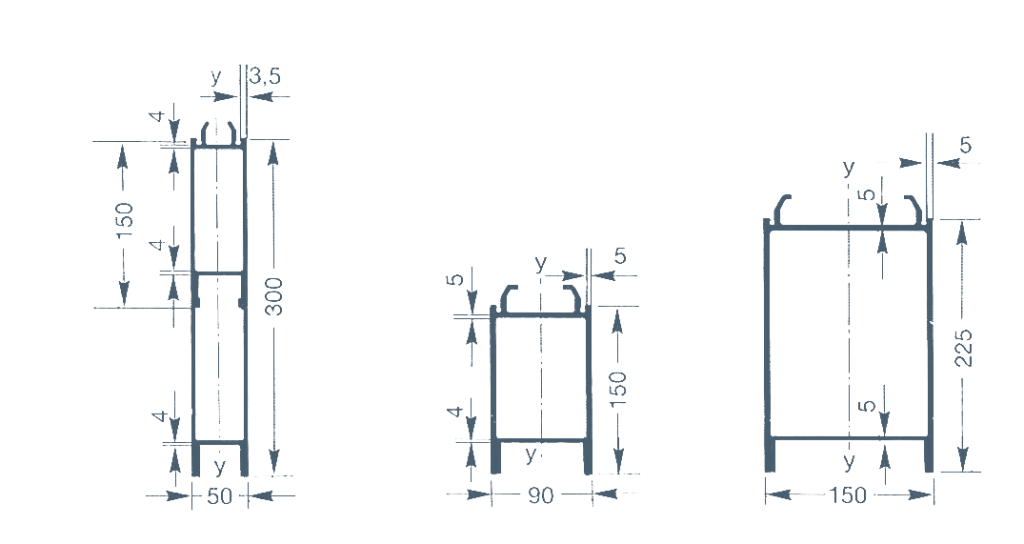

| Type/profile number | A/38192 | B/38193 | C/38194 |

| Weight per metre length | 8,51 kg/m | 7,26 kg/m | 11,17 kg/m |

| Weight per m² | 28,35 kg/m² | 48,42 kg/m² | 49,66 kg/m² |

| Moment of inertia ly | 137,7 cm⁴ | 363,9 cm⁴ | 1609,9 cm⁴ |

| Section modulus WY | 55,1 cm³ | 80,8 cm³ | 214,6 cm³ |

Sealing strips

EPDM Shore 60A

Seal between logs

Profile number M 02075

SEAL FOR INVERT AND GUIDE CHANNELS

Profile number M 02092

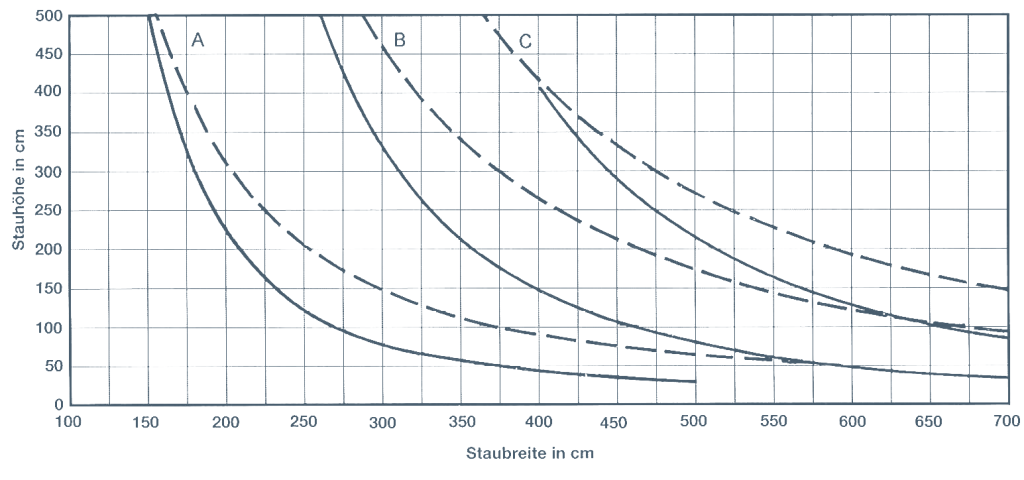

Maximum log cross-sections

using allowable stresses in the centre of the log, unwelded: zul σ = 95 N/mm², buckles at v ≤ 1,5, reference stress σv ≤; 0,75 x Rpo,2

at a max. deflection of 1/150 of the log span

Structural analysis of the shear strength, when held in the side channels within the limits shown in the diagram, is always possible, even with welded-on end caps. The extent to which the logs fit into the side channels (engagement depth) must be designed so that the logs cannot slip out accidentally. From a structural perspective, a support width of 2 cm is sufficient for analysis of the permissible pressure on the aluminium planks. However, the material or shape of the guide channel (concrete, wood) usually calls for greater support widths or engagement depths.